Heat shrinkage – use in electrical engineering

The development of Materials Science and Engineering, and in particular the understanding of polymerisation and catalysis mechanisms, has enabled the design and manufacture of polymer compositions with properties perfectly suited to specific applications. Due to their unique properties, polymers are used in all areas of life. In the electrical engineering industry, their insulating properties are mainly used, but their mechanical and chemical properties are equally important.

Achieving a heat-shrinkable effect in polymers has opened up new possibilities and resulted in the introduction of heat-shrinkable products to the market.

Heat shrinkage of materials.

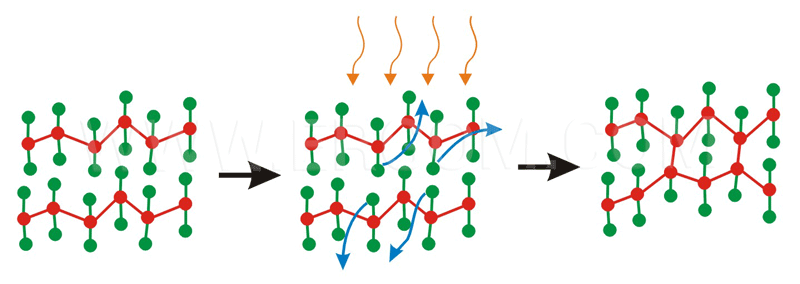

Heat shrinkage refers to the ability of a material to shrink as a result of heat treatment. This property can be induced in polymers by transforming their long carbon chains into a network structure. Under the influence of radioactive radiation, hydrogen atoms are knocked out of the carbon chains, and bonds are formed between neighbouring chains in these places, creating a specific network.

Polymers are thermoplastics; at elevated temperatures, their shape can be changed or stretched. Cross-linked polymers have shape memory after stretching – under the influence of heat, the material shrinks back to its original size. The level of cross-linking of the material determines its properties, e.g. shrink ratio or stiffness.

Polyolefins (mainly polyethylene) are usually used for electrical insulation purposes due to their good electrical and mechanical properties (strength and plasticity over a wide temperature range) as well as their moderate price.

Application of heat shrinkage in electrical engineering

Currently, the electrical engineering market offers products designed for low, medium and high voltages. Heat-shrinkable materials are mainly used for cable insulation, with the basic manufacturing form being a hose/tube. The market offers adhesive and non-adhesive tubes, in metre-long sections and rolls, in various colours. Other forms include lampshades, sheets, finger cots and heat-shrinkable tapes. In addition, heat-shrinkable materials are used to manufacture markers for labelling wires and cables.

How are heat-shrink products of specific shapes and dimensions manufactured?

Thermoplastic material (polymer), after being heated to the appropriate temperature, is pre-shaped by pressing or injection moulding. The finished part undergoes a cross-linking process through irradiation so that it ‘remembers’ its shape and dimensions. Then, again at an elevated temperature, the element is mechanically formed, e.g. stretched, to give it a shape that allows it to be applied to the object to be covered. In the next stage, heating is used to trigger the ‘shape memory’ and cause the element to shrink to its original shape or to the shape of the object on which it has been placed. If the heat-shrinkable cover is correctly selected, a precisely fitting layer with insulating, protective, anti-corrosive and sealing properties is formed on the protected object. Some heat-shrink products are coated on the inside with hot-melt adhesive to improve the tightness of the insulation.

Shrinkage ratio.

The basic parameter describing heat-shrinkable material is the shrinkage ratio (Table 1), which describes the ratio of the diameter of the heat-shrinkable element before and after shrinkage. Heat-shrinkable products used in electrical engineering have a shrinkage ratio of 2:1 to 6:1. A lower shrinkage ratio of 1,5:1 is used in heat-shrinkable tapes, where heat shrinkage is primarily used to achieve adequate coating tightness. Materials with high shrinkage ratios, i.e. 4:1 to 6:1, are more versatile due to the range of diameters they can handle, but at the same time they are significantly more expensive and are used in emergency situations when it is not possible to determine the required range of diameters of the insulated elements in advance.

Dielectric strength, volume resistivity.

Materials with high electrical parameters such as dielectric strength and volume resistivity are used to insulate live parts.

The basic material used for low voltages is polyethylene with a breakdown strength of 10÷18kV/mm and volume resistivity of 1012Ωm.

Modified polyolefins containing stabilizers and antioxidants are used for medium voltages. Their task is to improve resistance to cases characteristic of medium voltages, such as creepage currents. The dielectric strength of such material should be 24÷36kV/mm, and the volume resistivity should be of the order of 1015Ωm.

Heat shrinkage technology.

The main condition for obtaining good quality protection when using heat-shrinkable material is to select the right tool that ensures the correct shrink temperature.

For typical heat shrinkable materials, the shrink temperature should be between 100 and 200°C.

Thin-walled materials are shrunk using electric or gas heaters.

For shrinking larger and thicker materials such as sheets, sleeves, sleeves or heads (diameters from approx. 40 mm), it is recommended to use heaters - propane/butane gas burners.

Shrinking an element made of heat shrinkable material may cause a change in all its dimensions. Reducing the diameter of the shrink sleeve results in an increase in length, therefore sufficient space must be provided to prevent the material from wrinkling. For the same reason, it is important to choose the right place to start shrinking – the material can elongate in two directions, proportionally to its length.

Due to wide range of heat shrinkable materials that meet all quality standards and dedicated shrinking tools, ERGOM can provide comprehensive service at a reasonable price.

ERGOM offers heat-shrink: tubes, caps, breakouts, panels, straight through joints, pre-insulated pipe sealing cap.