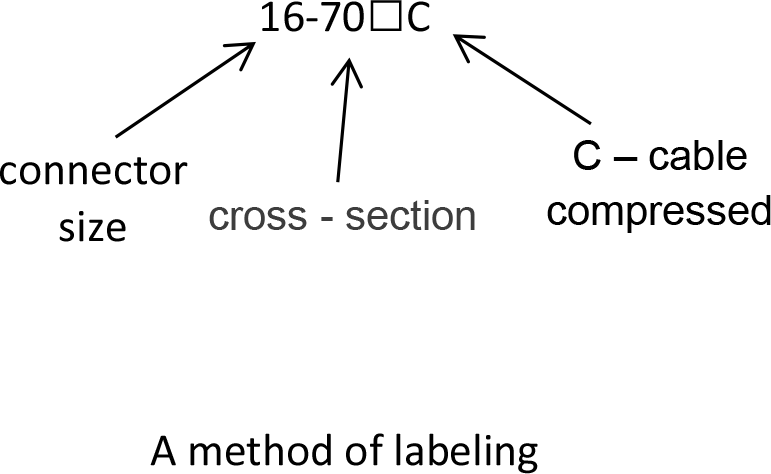

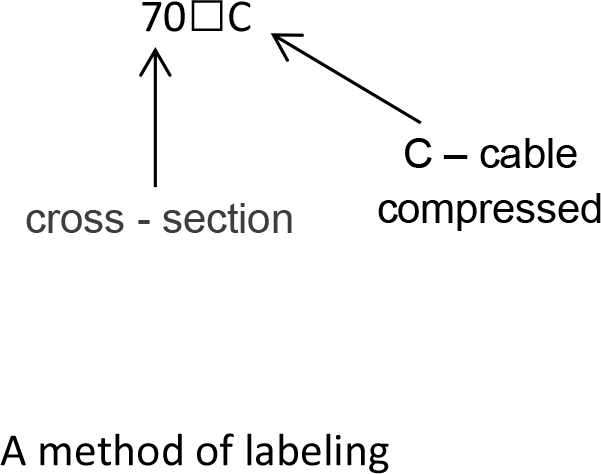

Innovation: Solutions for compressed cables

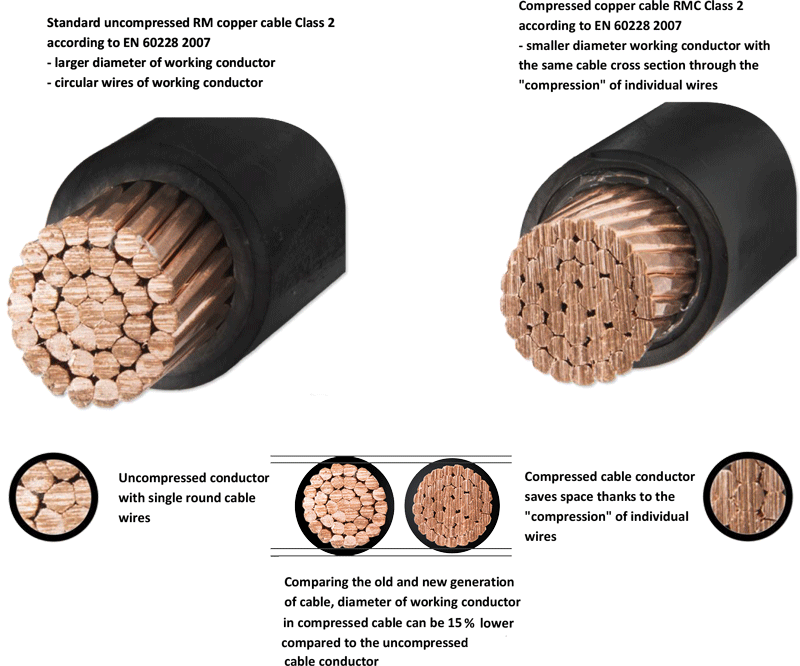

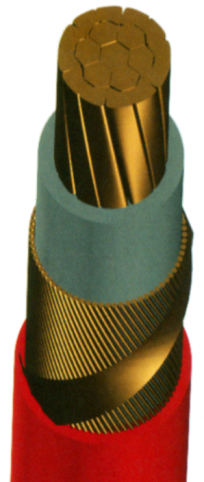

Cable manufacturers introduce to market new copper cables RMC Class 2 , which can have a diameter of working conductor up to 15 % less than their counterparts currently used (RM Class 2 ).

With the new construction, cable manufacturers can produce smaller and lighter wires while maintaining the same electrical parameters as in the past

However, a reduction in working conductor diameter has become a cause of serious problem. All produced cable terminals are designed for cables with a conductor structure of RM class 2 . Reducing the diameter of the wires in the new cable made the currently used cable terminals too big and cannot be properly crimped on the cable with thus far used tools and crimping dies.

COMPARISON OF CABLE PROFILES

|

cross-section [mm2] |

The diameter of the cable conductor profile according to PN-EN 60228 2007 |

The nominal inner diameter of cable terminals for RM Class 2 profile cables according to DIN 46235 [mm]

|

|

| Max [mm] | Min / Max [mm] | ||

|

Copper round multi-wire „RM” Class 2

|

Copper round multi-wire „RMC” Class 2 (“compressed”)

|

||

| 120 | 14,5 | 12,3 - 13,5 | 15,5 |

| 240 | 20,6 | 17,6 - 19,2 | 21,5 |

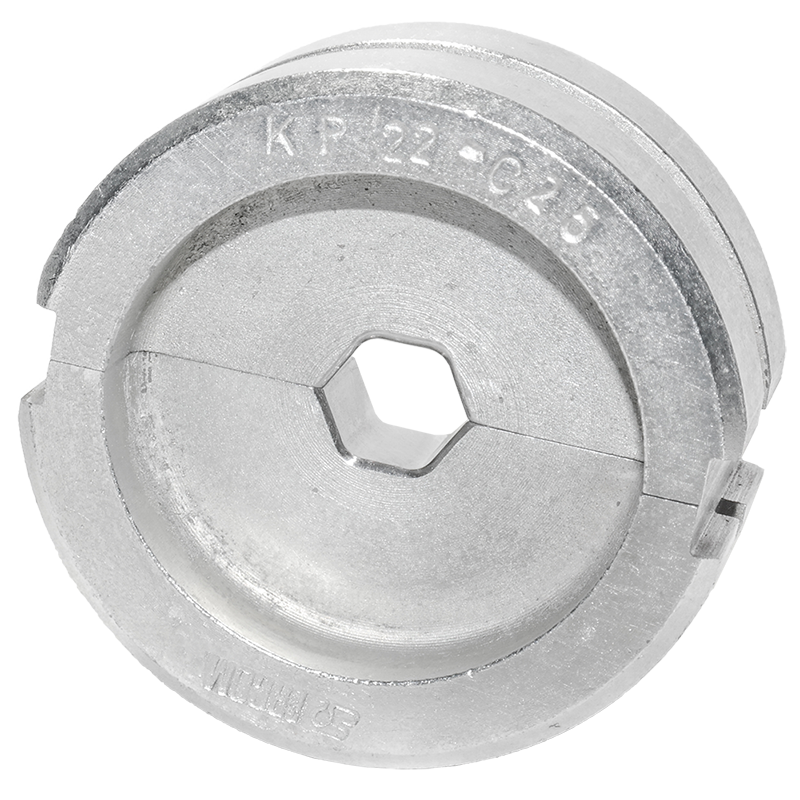

Using the standard produced cable terminal (for RM profile cables) and dedicated to the size of the socket crimping die to crimp on the RMC cable, we are not able to achieve the desired deformation, and thus the parameters of mechanical and electrical crimped connection does not meet requirements of PN -EN 61238-1 2004. It is possible to make a special crimping dies (socket size and shape) , but due to specified in the standard large range of outer diameters of compressed cables, this would require the creation of a number of crimping dies even for the same cross-section, depending on the manufacturer of the cable.

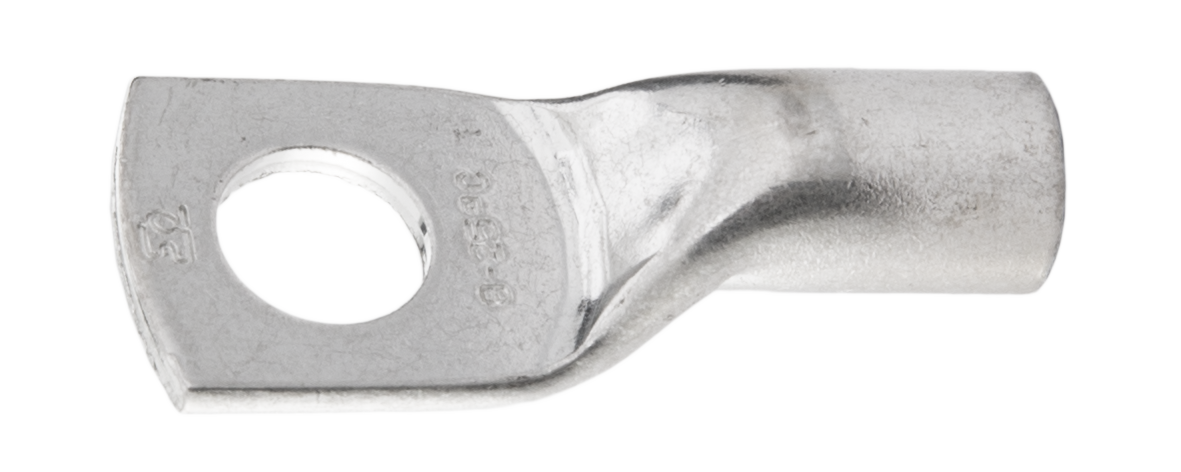

To solve this problem smartly, we have designed a special type of cable lugs CKOR and connectors CKOR, dedicated to copper cables of RMC Class 2 profile.

Both the terminals and connectors have their inner diameters tailored to smaller conductors of new compressed RMC cables. Especially for this set: compressed cable and terminal, we have designed proper crimping dies of appropriate socket size and crimping width.

| Type – made / size |

Copper cable Class 2 profile |

Cross-section 240 mm2 | ||

|

Ø Inner |

Ø Outer |

Crimping die socket size |

||

|

KOR – for standard cables

|

RM |

21,0 |

26,0 |

25 |

|

CKOR – for compressed cables

|

RMC |

20,6 |

26,0 |

C240 |

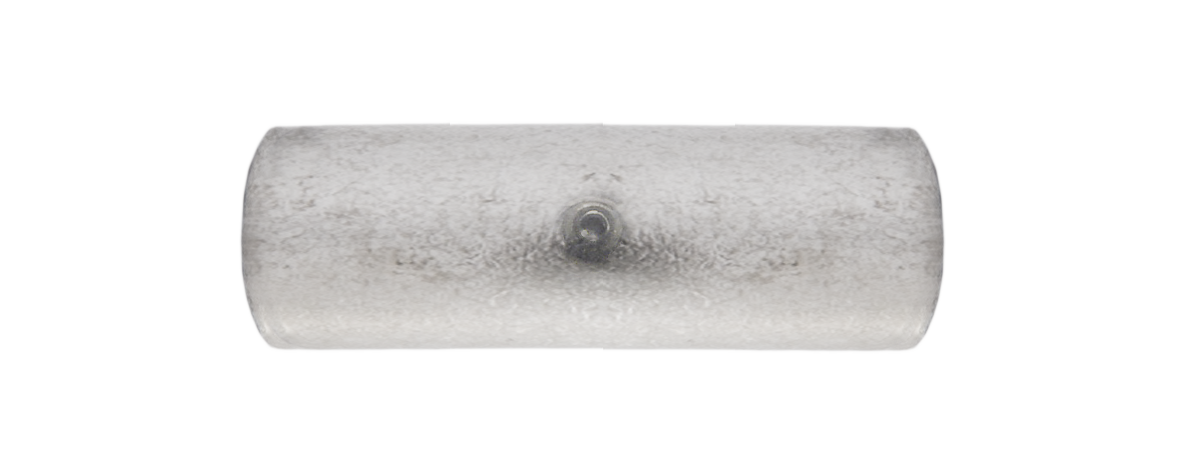

Cable terminals for compressed cables

|

|

|

|

||

| CKOR | CKL | ||||

| Material: | CU | Material: | CU |  |

|

| Surface |

tin-plated |

Surface |

tin-plated |

||

| Standard |

compressed |

Standard |

compressed |

||

|

Wire cross-section |

10 - 240 mm2 |

Wire cross-section |

10 - 240 mm2 |

||

|

|

|

Copper round multi-wire „RMC” Class 2 cable |

|||

Developed by our engineers system of terminal / connector and crimping die ensures quality connection on RMC cables in a reliable, fast and efficient way.